Latest Wholesale good quality hss slitting saw blade for cutting metal tube with workable price

Saw blade including hss circular saw blade,TCT circular saw blade,metal hot-cutting circular, metal cold-cutting circular hss circular saw blade , disc cutter, Slitting saw, HSS segmental circular hss circular saw blade , bimetal and carbide band saw blade and diamond circular saw blank .

Product Description

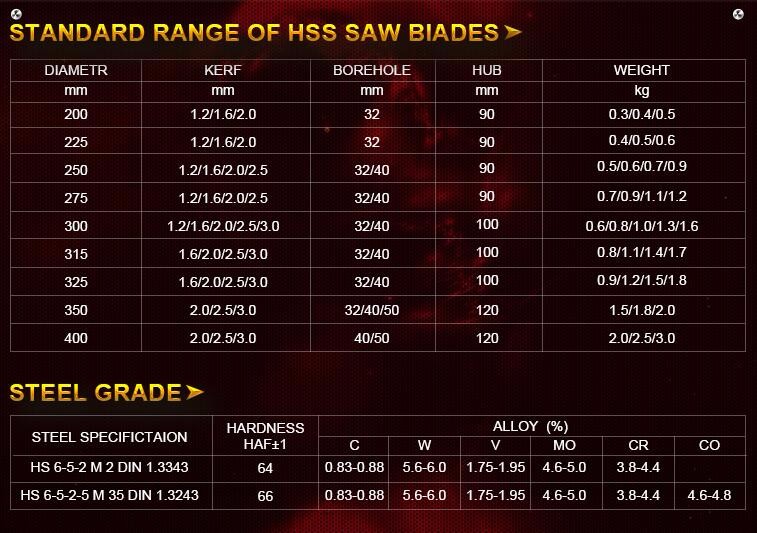

Diameter mm Bore

1.5" 40 5/8"to 2"

8" 200 5/8"to 2"

10" 250 5/8"to 2"

12" 300 5/8"to 2"

14" 350 5/8"to 2"

15" 400 5/8"to 2"

19" 500 5/8"to 2"

| HSS/ HSS-E DMo5 circular saw blade M2 M35 DIN 1.3343 DIN 1.3243 |

| Dia*thickness | Hole:From 5mm-32mm-40mm-50mm etc | | | | | |

| 20x0.2-3 | 25x0.2-6 | 32x0.2-6 | | | | |

| 40x0.2-0.8 | 75x6.5-7 | 125x0.8-1.2 | | | | |

| 40x1-1.5 | 75x7.5-8.5 | 125x1.5 | | | | |

| 40x2 | 80x0.5-0.8 | 125x2 | | | | |

| 40x2.5-3 | 80x1-1.2 | 125x2.5-3 | | | | |

| 40x3.5-4 | 80x1.5 | 125x3.5-4 | | | | |

| 40x4.5-5 | 80x2 | 125x5 | | | | |

| 50x0.5-0.8 | 80x2.5-3 | 125x5.5-6 | | | | |

| 50x1-1.5 | 80x3.5-4 | 150x1-1.2 | | | | |

| 50x2 | 80x4.5-5 | 150x1.5 | | | | |

| 60x0.3-0.4 | 80x5.5-6 | 150x2 | | | | |

| 60x0.5-0.8 | 80x6.5-7 | 150x2.5-3 | | | | |

| 60x1-1.2 | 80x8 | 150x3.5-4 | | | | |

| 60x1.5 | 100x0.5-0.8 | 150x4.5-5 | | | | |

| 60x2 | 100x1-1.2 | 150x5.5-6 | | | | |

| 60x2.5-3 | 100x1.5 | 150x6.5-7 | | | | |

| 60x3.5-4 | 100x2 | 150x7.5-8.5 | | | | |

| 60x4.5-5 | 100x2.5-3 | 160x1-1.2 | | | | |

| 63x0.5-0.8 | 100x3.5-4 | 160x1.5 | | | | |

| 63x1-1.2 | 100x4.5-5 | 160x2 | | | | |

| 63x1.5 | 100x5.5-6 | 160x2.5-3 | | | | |

| 63x2 | 100x7 | 160x3.5-4 | | | | |

| 63x3 | 100x8 | 160x4.5-5 | | | | |

| 75x0.5 | 110x0.8-1.2 | 160x5.5-6 | | | | |

| 75x0.6-0.8 | 110x1.5 | 200x1.5 | | | | |

| 75x1-1.2 | 110x2 | 200x2 | | | | |

| 75x1.5 | 110x2.5-3 | 200x2.5-3 | | | | |

| 75x2 | 110x3.5-4 | 200x3.5-4 | | | | |

| 75x2.5-3 | 110x4.5-5 | 200x4.5-5 | | | | |

| 75x3.5-4 | 110x5.5-6 | 200x5.5-6 | | | | |

| 75x4.5-5 | 110x7 | 200x6.5-7 | | | | |

| 75x5.5-6 | 110x8 | 200x7.5-8.5 | | | | |

| 225x2 | 250*1.0-2.5 | 275x1.0-2.5 | | | | |

| 300x1.2-3.0 | 315x2.0-3.0 | 325x2.0-2.5 | | | | |

| 350x2.0-3.0 | 370x2.5 | 400x2.0-3.0 | | | | |

| 425x3.0 | 450x3.0 | 500x3.0-4.0 | | | | |

| T.C.T circular saw blade for Aluminum Brass etc | | |

| Dia* thickness*hole | | Teeth No.BW/BS |

| 250x4.0/5.0/6.0/7.0/8.0x25.4 | | 40/60/80/100/120 |

| 255x3.2/2.8/2.0x25.4 | | 60/80/100/120 |

| 300x3.0/2.8x25.4 | 60/80/100/120 |

| 305x3.0/2.8x25.4 | 60/80/100/120 |

| 355x3.5/3.2x25.4 | 60/80/100/120 |

| 405x3.8/3.2x25.4 | 60/80/100/120 |

| 455x4.2/4.0x25.4/30 | | 60/80/100/120 |

| 500x4.4/4.0x25.4/30 | | 60/80/100/120 |

| 510x4.4/4.0x30/40/50 | | 60/80/100/120/144 |

| 550x4.4/4.0x32/40/50/80 | | 60/80/100/120/144 |

| 560x5.0x32/40/50/80 | | 48/100/120 |

| 600x5.0/4.0x32/40/50/80 | | 50/60/80/100/120 |

| 650x5.0/4.0x32/40/50/80 | | 60/80/100/120 |

| 700x6.0/5.0x32/40/50/80 | | 60/80/100/120 |

| 710x6.0/5.0x50/60/80/100 | | 60/80/100/120 |

| 750x7.0/6.5x50/60/80/100 | | 60/80/100/120 |

| 800x7.0/6.5x50/60/80/100 | | 60/80/100/120 |

| 850x8.0/7.5x50/60/80/100 | | 60/80/100/120 |

| 900x8.0/7.5x50/60/80/100 | | 60/80/100/120 |

| 910x8.0/7.5x50/60/80/100 | | 60/80/100/120 |

| 1000x10.0/8.0x50/60/80/100 | | 60/80/100/120 |

| 1050x10.0x50/60/80/100 | | 60/80/100/120 |

| 1100x10.0/9.0x80/100/120150 | | 60/80/100/120 |

| 1200x10.0/9.0x80/100/120/150 | | 60/80/100/120 |

| 1250x10.0x80/100/120/150 | | 60/80/100/120 |

| 1430x10.0x80/100/120/150 | | 120/150 |

| 1450x10.0x80/100/120/150 | | 120/150 |

| 1750x11.0x80/100/120/150 | | 150 |

| circular saw blade for cold cutting | | |

| 160x1.8x40 | 48T |

| 200x2.0x40 | 54T |

| 230x2.0x40 | 60T |

| 250x2.0x32 | 54/60/72/120 |

| 285x2.0x32 | 60/72/80 |

| 315x2.25x32 | 60/72/80/100/120/140 |

| 360x2.6x40 | 60/80/100/120/130/140 |

| 425x2.5x50 | 80T |

| 425x2.7x50 | 80/100 |

| 460x2.7x50 | 60/80/100 |

Teeth:

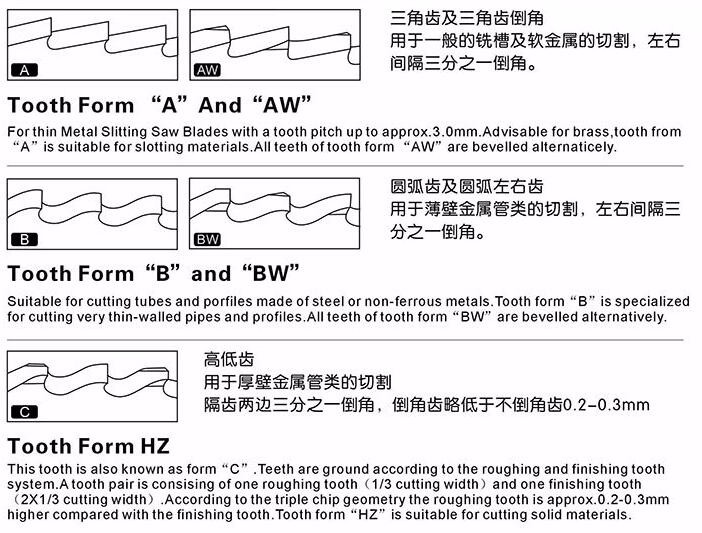

The different kinds of tooth forms are used according to different requirements of cutting.

How to choose the right tooth form?

1.Tooth form "A" and "AW"

For thin Metal Slitting hss slitting saw blade for cutting metal tubes with a tooth pitch up to approx. 3.0mm Advisable for brass, tooth form "A" is

suitable for slotting materials. All teeth of tooth form "AW" are bevelled alternatively.

2.Tooth form "B" and "BW"

Suitable for cutting tubes and profiles made of steel or non-ferrous metals. Tooth form "B" is specialized for cutting very thin walled popes and profiles. All teeth of tooth form "BW" are bevelled alternatively.

3.Tooth form HZ

This tooth is also known as form "HZ". Teeth are ground according to the roughing and finishing tooth system. A tooth pair is consisting of one roughing tooth(1/3 cutting width) and one finishing tooth(2x1/3 cutting width). According to the triple chip geometry the roughing tooth is approx.0.2-0.3mm higher compared with the finishing tooth. Tooth form "HZ" is suitable for cutting solid materials.

4.Tooth Form BR

Tooth form BR is a parrot tooth with chip breaker.This tooth form is sutiable for cutting pipes under high performance conditions because the teeth are side cutting.

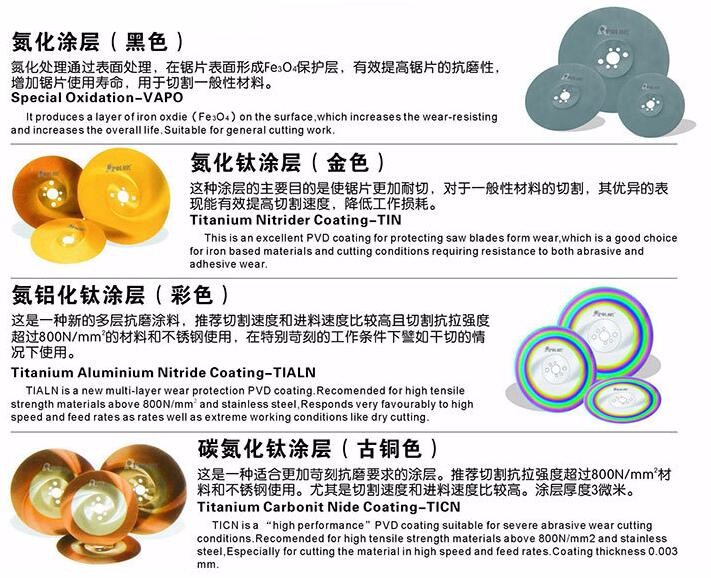

Finishing Color:

Company Information

Contact US Or Send Us inquiry ↓ ↓ ↓